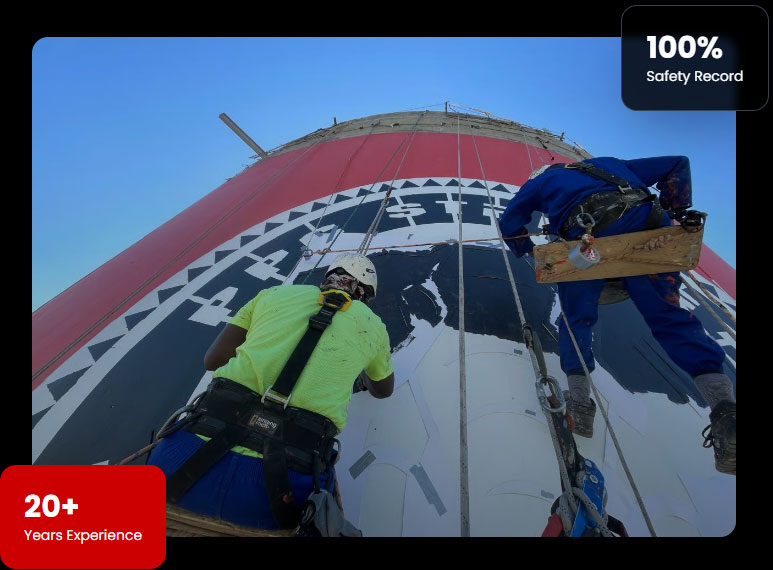

At Ascend Rope Access, we provide professional anchor point installation, inspection, and certification for buildings, warehouses, and high-rise structures. Our IRATA-certified technicians ensure safe and compliant anchor systems that meet industry standards, giving you complete confidence when working at height.